The 6-Step Production Process for Recycled Wool Fabric in Chinese Mills

— recycled wool fabric mill’s production steps

The global textile recycling market, which includes wool recycling, is projected to reach $11.88 billion by 2030, reflecting increasing demand for sustainable alternatives . This growth is largely driven by fashion brands and consumers seeking to reduce the environmental impact of clothing production. Recycled wool fabric addresses this need by diverting textile waste from landfills while conserving the natural resources required for virgin wool production.

Chinese mills have positioned themselves as leaders in this sustainable transformation, leveraging decades of textile manufacturing expertise to develop efficient wool recycling processes. The country’s robust textile infrastructure and commitment to eco-friendly innovation have made it a hub for high-quality recycled woolen fabrics that meet international standards for both quality and sustainability .

Step 1: Meticulous Raw Material Collection and Sorting

The creation of premium recycled wool fabric begins with sourcing the right raw materials. Chinese mills utilize various wool waste sources, including:

-

Post-consumer garments like used wool clothing

-

Pre-consumer manufacturing waste from textile mills

-

Garment factory cutting scraps and leftover yarns

At this crucial stage, workers hand-sort materials by color and wool composition. This manual process ensures that only compatible materials are processed together, maintaining quality throughout production. Color sorting is particularly important as it enables mills to create new fabrics with minimal dyeing, further reducing the environmental impact .

(wool materials for recycled wool fabric)

Step 2: Fiber Processing and Preparation

Once sorted, the wool materials undergo fiber reclamation. The fabrics are cleaned and sterilized before being processed through specialized machines that shred them back to their fibrous state. This process breaks down the existing textile structures without damaging the fundamental wool fibers.

The resulting wool fibers are typically shorter than virgin wool fibers, which affects the spinning process. To compensate for this fiber shortening and ensure structural integrity, mills often blend the recycled wool with reinforcement fibers. These might include virgin wool, polyester, or other materials that help create a more durable yarn .

(yarn making for recycled wool fabric)

Step 3: Innovative Spinning Techniques

The processed wool fibers then move to spinning mills where they’re transformed into yarn. Advanced spinning systems create consistent, high-quality yarns from the recycled materials. The blending of fiber lengths and types happens at this stage, optimizing the yarn’s performance characteristics.

Chinese mills have developed expertise in working with the unique properties of recycled fibers, adjusting traditional spinning parameters to accommodate shorter fiber lengths while maintaining yarn strength and consistency. The result is a versatile recycled wool yarn suitable for weaving high-quality fabrics.

(spinning for recycled wool fabric)

Step 4: Creative Weaving and Design

With the yarn prepared, the weaving process begins. This is where the technical expertise of Chinese mills truly shines. Designers and technicians collaborate to create various recycled wool fabric structures:

-

Traditional plain weaves for classic apparel

-

Twill patterns for durable outerwear

-

Complex jacquard designs for fashion garments

The weaving process transforms the recycled yarns into textile greige goods (unfinished fabric). Modern looms precisely interlace warp and weft yarns, creating the foundation for the final fabric. The expertise at this stage ensures that the resulting textiles meet precise specifications for weight, density, and drape.

(finished yarns for recycled wool fabric)

Step 5: Quality-Enhancing Finishing Processes

The unfinished fabrics undergo specialized finishing treatments to enhance their appearance and performance. These processes may include:

-

Washing and fulling to soften the hand feel

-

Raising or brushing to create surface texture

-

Heat setting to stabilize dimensions

-

Eco-friendly dyeing (when color addition is necessary)

The finishing stage is particularly important for recycled wool fabrics as it helps create the luxurious hand feel that often surpasses even virgin wool fabrics. The repeated processing actually contributes to this enhanced softness, making the final product exceptionally comfortable while maintaining durability .

(weave prepare for recycled wool fabric)

Step 6: Quality Assurance and Sustainable Certification

Before distribution, the finished recycled wool fabric undergoes rigorous quality control checks. Chinese mills typically test for:

-

Fabric weight and thickness

-

Tensile and tear strength

-

Colorfastness

-

Shrinkage resistance

-

Performance standards

Many mills also pursue third-party sustainability certifications like OEKO-TEX Standard 100 or Global Recycled Standard, providing customers with verified assurance of the fabric’s eco-friendly credentials and safety.

(make the greige recycled wool fabric loose for later process)

Why Chinese Recycled Wool Fabrics Gaining Global Appeal?

The market for sustainable fabrics is experiencing significant growth, projected to exceed $115.7 billion by 2035 . Chinese recycled wool fabrics have gained international recognition not just for competitive pricing, but for their proven quality and authentic sustainability.

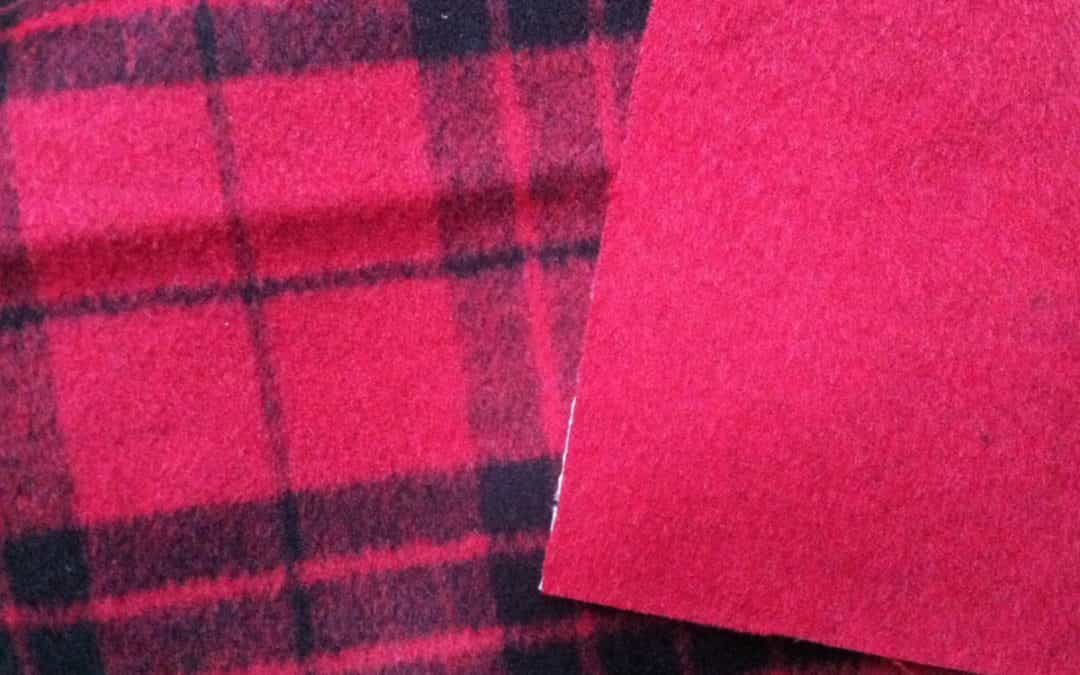

International fashion brands are increasingly sourcing these materials for their environmental benefits and unique characteristics. The distinctive texture and depth of color achieved through the wool recycling process create visually interesting fabrics that stand out in the marketplace .

Leading global textile manufacturers like Kvadrat have developed their own high-quality recycled wool products, demonstrating the material’s acceptance in premium markets . This mainstream adoption has further validated China’s position as a producer of quality recycled wool textiles.

(final recycled wool fabric)

Environmental Impact: The Sustainable Advantage

The production of recycled wool fabric offers substantial environmental benefits compared to virgin wool production:

-

Reduced landfill waste from textile diversion

-

Lower water consumption than virgin wool processing

-

Minimized chemical usage through color-sorting techniques

-

Decreased energy requirements for fiber processing

-

Conserved natural resources through circular economy principles

Italian textile regions like Prato have practiced wool recycling for centuries, proving the long-term viability of this approach . Chinese mills have adapted and modernized these traditions, creating efficient systems that support global sustainability goals while meeting market demands for quality and performance.

(recycled wool fabric women coat)

Conclusion: The Future of Recycled Wool Fabrics from China

Recycled wool fabric production represents a successful marriage of environmental responsibility and commercial viability in China’s textile industry. The sophisticated 6-step process demonstrates how traditional manufacturing expertise can evolve to meet contemporary sustainability challenges.

As global demand for eco-friendly materials continues to grow, Chinese mills are well-positioned to lead the recycled wool fabric market through continued innovation and quality improvement. The combination of technical expertise, manufacturing scale, and commitment to sustainability creates a compelling value proposition for international brands seeking to enhance their environmental credentials without compromising on quality.

For businesses interested in exploring recycled wool fabric options, Chinese manufacturers offer extensive experience in custom development, sourcing, and production, making them ideal partners for sustainable fashion initiatives. Contact us now!